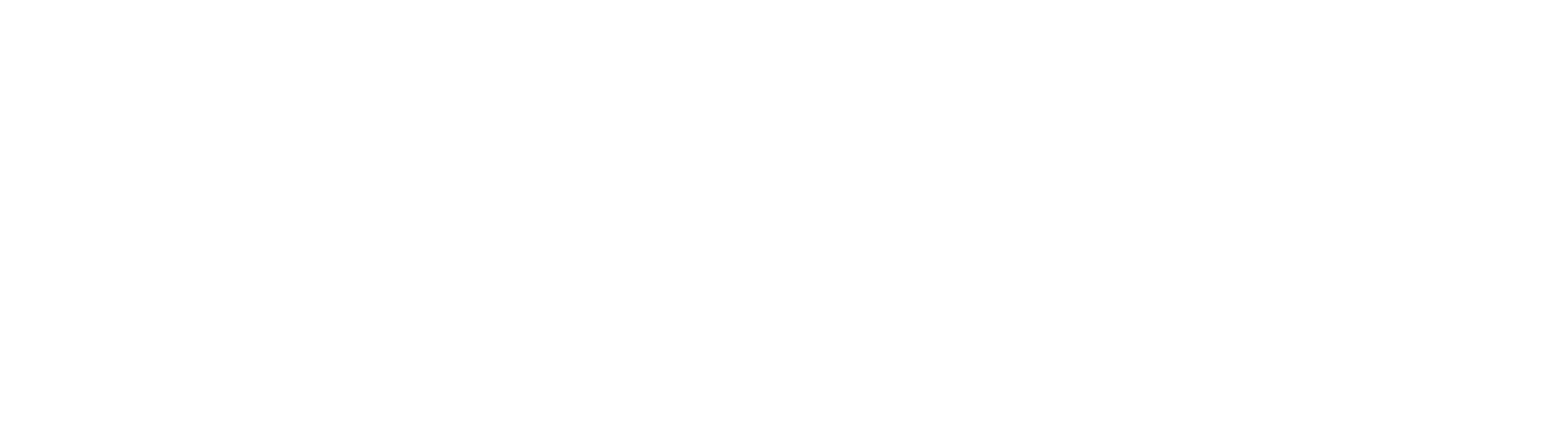

PCS inverters have been widely used in various fields such as renewable energy grid connection, distributed power generation and AC/DC microgrids, electric vehicle energy storage applications, power transmission and distribution, and auxiliary services. In order to ensure the healthy and friendly grid operation of energy storage systems, during the industrial "R&D-production-testing" iteration process, research and test engineers need to repeatedly modify controller parameters and test conditions to conduct a series of energy storage inverter tests under different operating conditions. Based on the characteristics of building arbitrary topology models and high accuracy using semi-physical simulation, the adoption of Hardware-in-the-Loop (HIL) semi-physical hardware testing for energy storage system grid connection has gradually become a mainstream trend.

Technology

Technology

User Cases

User Cases