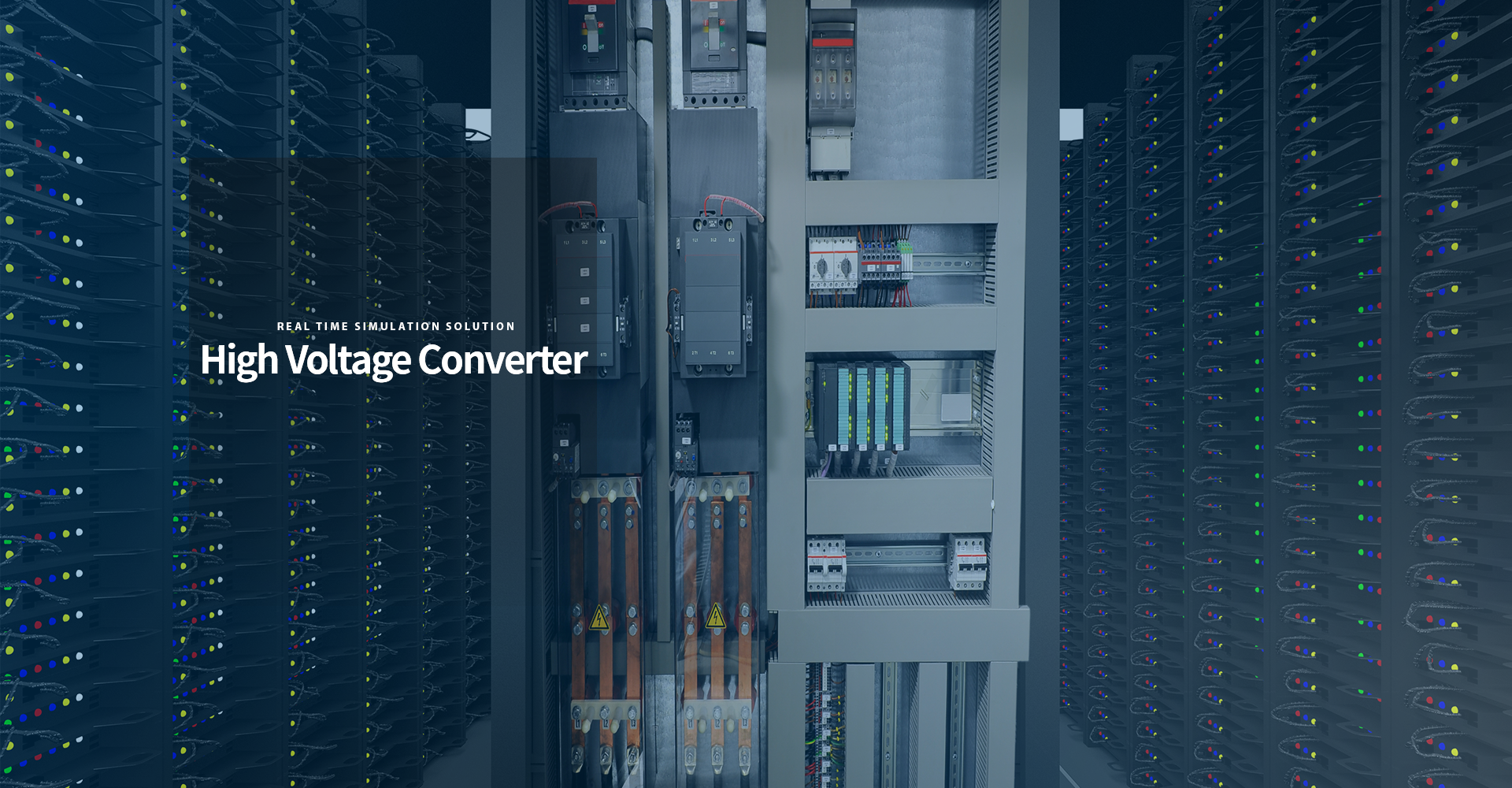

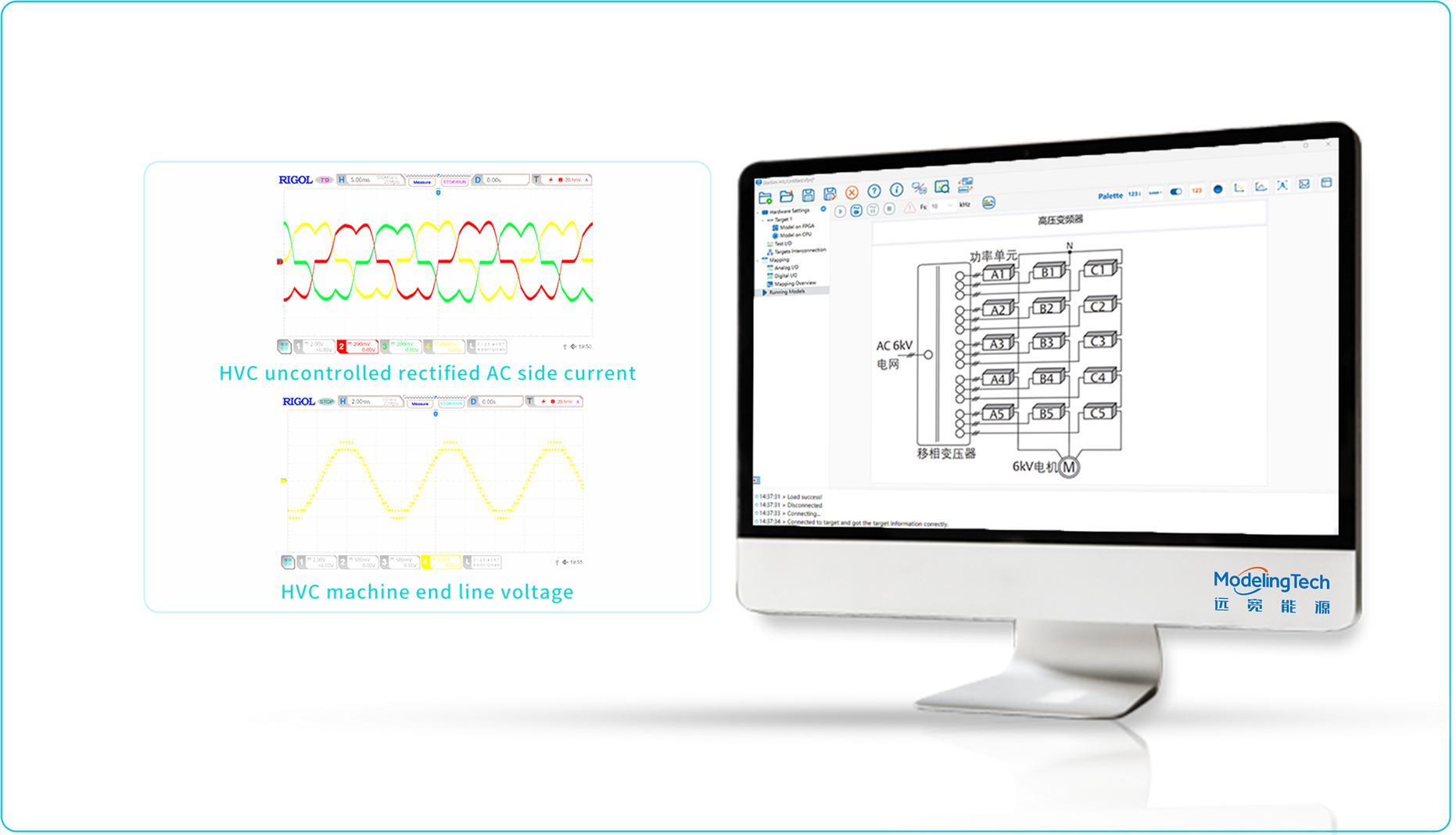

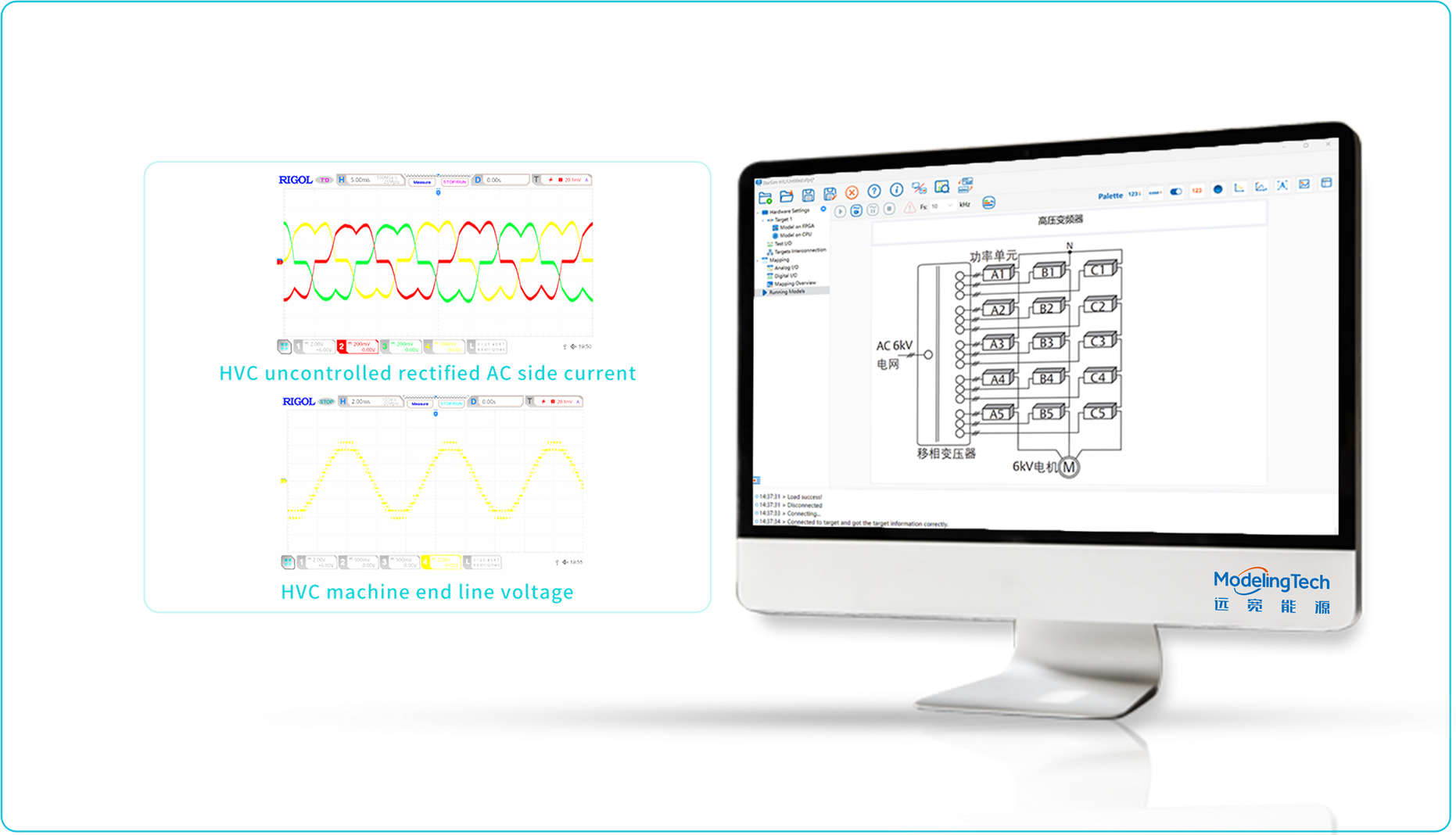

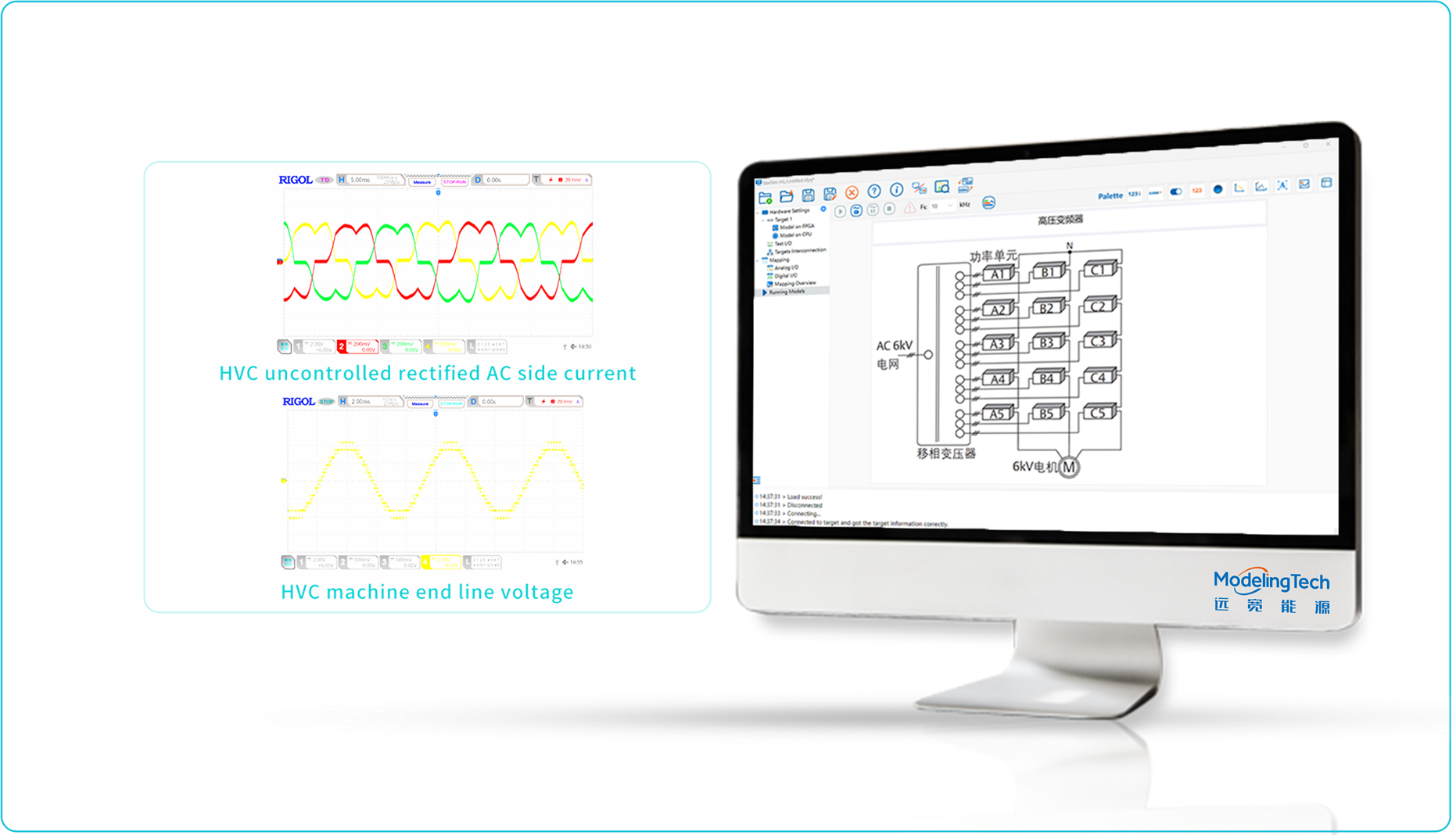

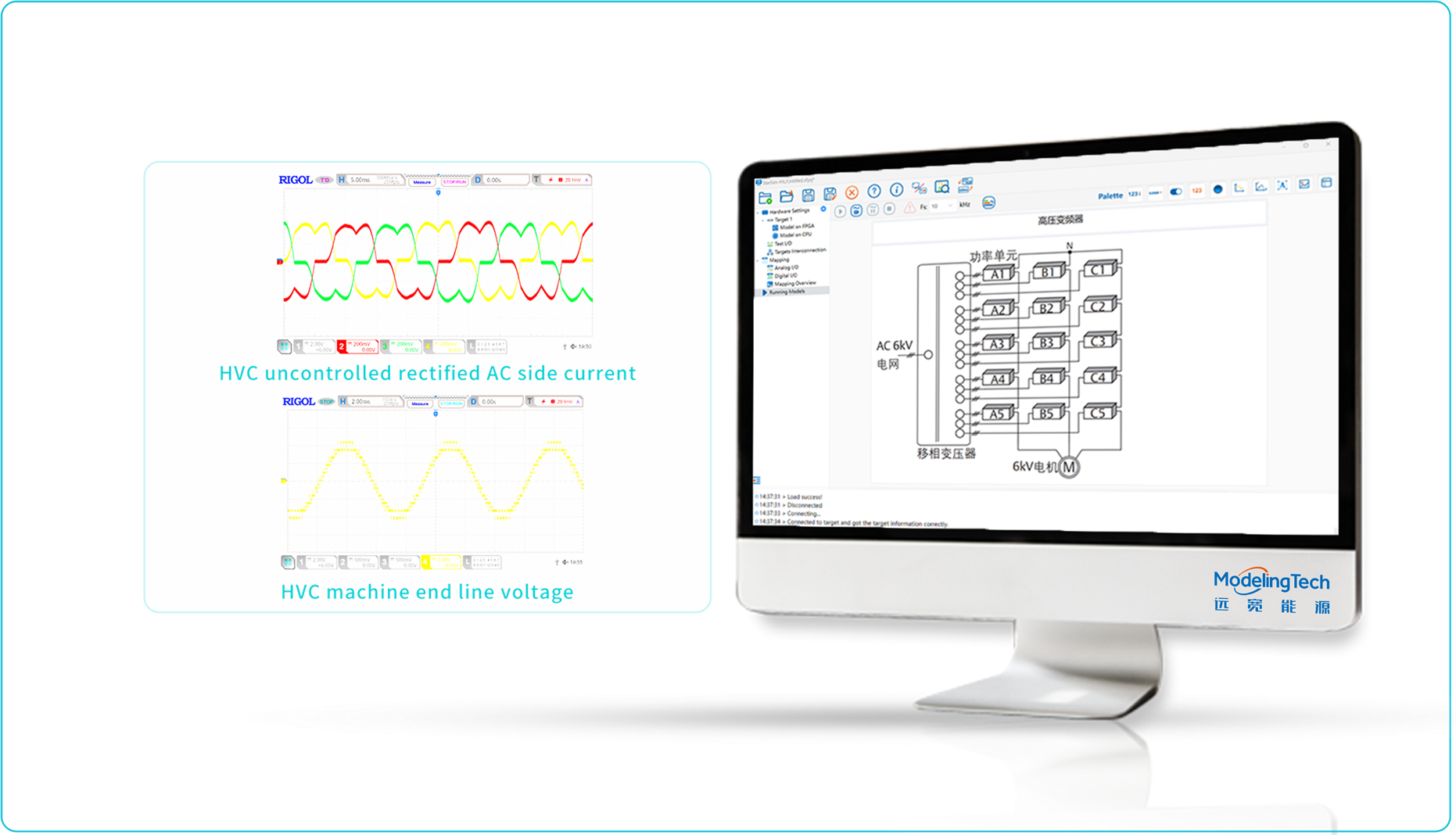

High voltage converter (HVC) are widely used in metallurgy, chemical industry, mining, shipping and many other industrial fields, and have gained wide recognition from users in reducing the energy consumption of electric motors, improving the control level of the drive system, frequency conversion soft starting, and improving the power factor and efficiency of equipment. HVC exists higher voltage level, complex topology, testing difficulties and other issues, in order to ensure that the high-voltage inverter efficient, safe and reliable operation, in the industrial reality of the "R & D - production - test" product iteration links, R & D test engineers have to repeatedly modify the controller parameters, circuit parameters in order to carry out a series of HVC testing in different operating conditions, based on the semi-physical simulation to support any topology model building and highly accurate features,the use of hardware-in-the-loop solutions for the development and testing of HVC has become a mainstream trend nowadays.

Technology

Technology

User Cases

User Cases